Production equipment / techniques to produce high-quality, precise products.

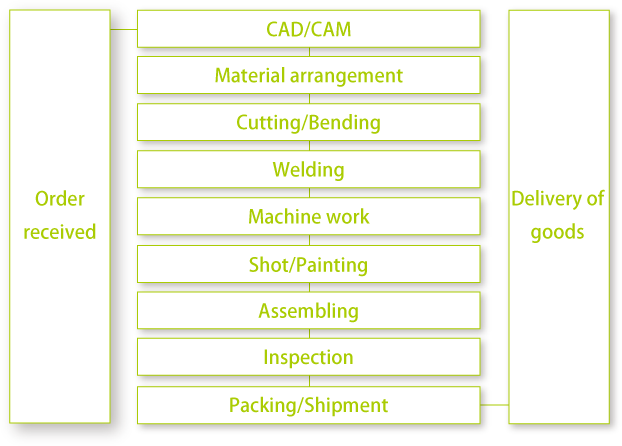

Consistent production from receiving an order to delivery of the goods

Main production equipment(Unit: mm)

Laser Process Machine (TRUMPF TruLaser3030fiber)

Output: 4KW 3050×1525, Soft steel: up to 25mm(thickness)

CNC Down-type Press Brake

(TRUMPF Trubend5230 B03)

Press force 2300KN Length of bend 3230mm

Welding Robot System (Kobe Steel)

Loading mass: 2500kg, Right/Left: 4000, Up/Down: 1500, 11axes

Machining Center with Five-face Machining Equipment (Okuma MCR-A5C)

X4000, Y2550, Z1650

Horizontal Boring NC milling

(Toshiba Machine BTD-110H R-161)

X2000×Y1500×Z1450×W500

Shot Blast

(Nicchu H2500×φ3300)(Nicchu H2500×φ2000)

List of Main Production Equipment(as of Apr. 2023)

| Equipment Name | Maker Model | Ability (X× Y× Z) Unit:mm | Number |

|---|---|---|---|

| Laser Process Machine | TRUMPF TruLaser3030fiber | 4kw 3050×1525 (6-Stage Pallet Master) | 1 |

| Mitsubishi ML3015eX-45CF-R | 4.5kw 3050×1525 | 1 | |

| Machining Center with Five-face Machining Equipment |

Okuma MCR-A5C | 2550×4000×1650 | 2 |

| Vertical Machining Center | OKK VM900 | 2060×940×820 | 1 |

| OKK VM76R | 1540×760×660 | 1 | |

| OKK VM5Ⅲ | 1020×510×510 | 1 | |

| OKK VM43R | 630×430×460 | 1 | |

| Horizontal Machining Center | OKK HM1000S | 1400×1100×1000 | 1 |

| OKK HM100S | 1400×1100×1000 | 1 | |

| OKK HM6000S | 800×750×880 | 1 | |

| OKK HM600 | 800×750×880 | 1 | |

| NC Lathes | Hitachi Seiki TF25 | φ350 | 1 |

| Horizontal Boring NC milling | Shibaura Machine BTD-110H R-16 | 2000×1500×1450 | 1 |

| Shibaura Machine BTD-110S. R-16 | 2000×1500×1450 | 1 | |

| Boring Machine | Shibaura Machine | 1000×800×500 | 1 |

| Radial Drilling Machine | Ikeda, Wakayama | L1300, L1500 | 2 |

| Press Brake | TRUMPF TruBend5230(B03) | 230t L4000 | 1 |

| Amada HDS-1703NT | 170t L3000 | 1 | |

| Amada HG-1003ATC | 100t L3000 | 1 | |

| Press, Univan | Aida Engineering | 80t, 60t, 35t | 4 |

| Pipe Bender | Taiyo DR-1HA, GM35 | Round pipe, and others (depends on the model) | 2 |

| Welding Robot System | Kobelco (with positioner) | Work 3t Right/Left 5000 Up/Bottom 1500 11axes | 1 |

| Work 1.5t Right/Left 3000 Up/Bottom 1000 10axes | 1 | ||

| Work 1.5t Right/Left 3000 9axes | 2 | ||

| Work 500kg 8axes | 6 | ||

| Panasonic (with positioner, 2 machines) | Reach 1800 6axes | 2 | |

| Reach 1800 6axes | 3 | ||

| FANUC | Reach 1600 6axes | 1 | |

| Lifting-type Cantilever 3 axis Positioner | Line Works NSK2000L | Work 2t | 2 |

| Line Works NSK1000L | Work 1t | 2 | |

| Amada CWT-1000 | Work 1t | 1 | |

| 3D Welding Table | Siegmund | 3000×1500×200 | 1 |

| 2400×1200×200 | 1 | ||

| 1500×1000×200 | 1 | ||

| Welding Positioner | Matsumoto Kikai | Work 1t-1machine For round objects-2 machines | 3 |

| CO2 Welding Machine | Panasonic, Daihen | 350A, 500A | 50 |

| TIG Welding Machine | Panasonic | 3 | |

| Ark Welding Machine | Hitachi, Panasonic | 4 | |

| Spot Welding Machine | Nastoa SLP-35B5 | 1 | |

| Automatic Sawing Machine | NICOTEC | 1 | |

| Press Machine | Osaka Jack, Komatsu Manufacturing | 4 | |

| Straightening Machine | Komatsu Manufacturing | 1 | |

| Shot Blast | Nicchu | Work 2.5t φ3300×H2500 | 1 |

| 〃 | Nicchu | Work 2t φ2000×H2500 | 1 |

| 〃 | SINTO KOGIO,LTD | Work 2t φ1600×H3200 | 1 |

| Paint Booth | ANEST IWATA, ANDEX | Work 2t length up to 5.5m | 3 |

| Overhead Traveling Crane | Kito, Nippon Hoist | 2.8t-5engines, 2t-14engines, 1t-7engines | 26 |

| Jib Crane, Light crane | Kito, Nippon Hoist | 2t-1engine, 500kg-3engines, 250kg-9engines, 100kg-5engines | 18 |

| Forklift | Komatsu, Mitsubishi Logisnext | 4t-1 machine, 2.5t-3 machines, 1.5t-1 machine | 5 |

| Truck | Isuzu, Mitsubishi | 4t wing-2 trucks, 2t flat-bed 1 truck | 3 |

| Commercial Car | Toyota | Aqua, Hiace, Probox | 3 |

| Articulated 3-Dimensional CMM | Tokyo Boeki TS, Kosaka Laboratory | Contact/Noncontact 3500×3500×3312 | 2 |

| CAD/CAM | SolidWorks, Auto CAD, Meta CAM, EXCESS-HYBRID, VPSS3i-Bend, etc. | 11 |